Orton Cone Chart

Orton Cone Temperature Equivalents

Download and Print the Complete Orton Cone Wall Chart... Here.

Download and Print the Complete Orton Cone Wall Chart... Here.

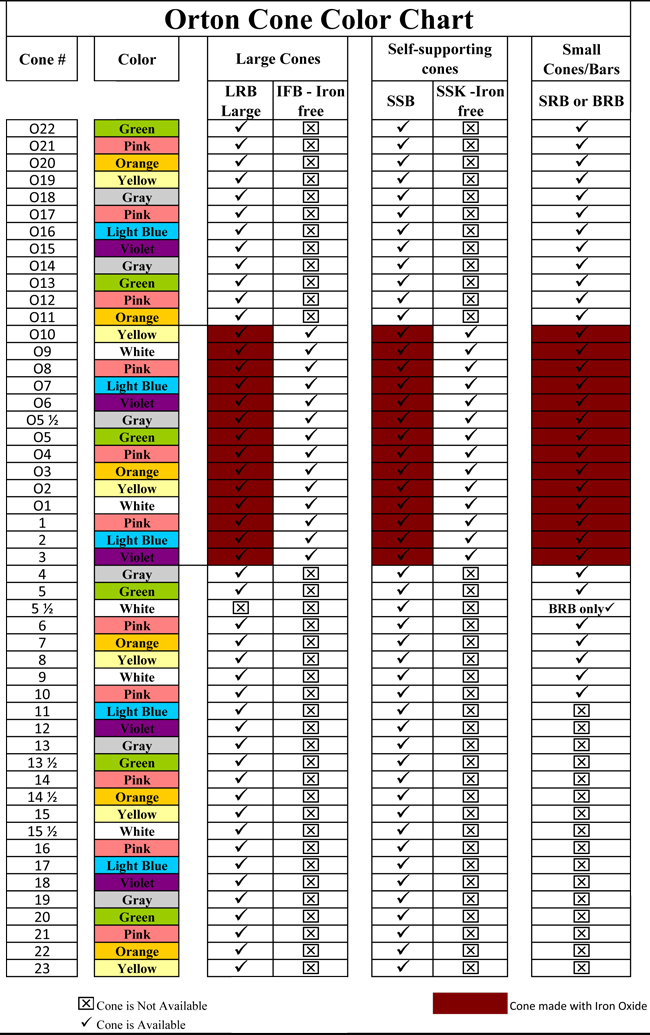

There are four different types of Orton cones and bars (Small cones, Bar cones, Large cones, and Self-supporting cones).

MIX AND MATCH BOXES FOR AN AUTOMATIC 10% DISCOUNT!

EASY SHIPPING INCLUDED PRICES!

Cones are essential monitoring for all kilns.

We have kilns for sale for every need: shop kilns here

What do the colors of Orton Cones and Bars mean?

Orton cones and Bars have 11 different colors. Knowing the colors can make it easier to tell at a glance which cone you have. Cones have their number stamped on the side and that is the most important thing to look at since there are colors shared by different cones. There are 10 different colors that span Large and Self Supporting as well as Small Cones and Bars. Cones and Bars from 05 to 3 are dark red because of the iron that they contain.

Here is a guide to Orton cones colors.

The Large and Self-supporting cones are used to measure temperature uniformity and/or if there was sufficient heatwork done to mature the ware. Cones indicate whether the ware received an adequate amount of heatwork to properly mature the clay or glaze. A properly fired cone will bend over with the tip of the cone almost touching the shelf. After firing a kiln, a simple glance at the cone can tell if the firing was successful.

The small and bar cones are mainly used in the kiln shut-off device called the Kilnsitter. This is a mechanical device that shuts off the kiln when the temperature inside is sufficient to cause the cone to deform under the weight of the Kilnsitter rod.

The only true measurement of heatwork is from a Large or Self-supporting cone placed on the shelf next to the ware.

CONE NUMBERS - Orton makes cones from cone 022 up to cone 42. Cone 022 is the lowest melting cone and requires the least amount of heat to deform or bend. During firing, a cone softens and melts as it is heated. Cones used on the kiln shelf bend due to the effects of gravity pulling the tip down. This bending indicates the cone and the ware have received a specific amount of heat. It typically takes 15 to 22 minutes for cones to bend fully once they start bending. Each higher cone number requires more heat to bend. A cone 01 needs less heat treatment than cone 1 and cone 020 needs less than 019.

It is important not to confuse the lower maturing cones and bars, whose numbers begin with an 0, with the higher cones and bars not containing this prefix.

Although cones do not actually measure temperature, cone bending behavior and temperature are related. Generally, the faster the firing, the higher the temperature required to bend the cone and the slower the firing, the lower the temperature required to bend the cone. The 6 oclock position (90 angular degrees) is considered the end point of cone bending.

Typical uses for cone numbers are as follows:

NUMBER: 022 TO 011 - Used in firing of overglaze decorations, lusters, enamels, and decals and for glass fusing, slumping, and decorating. The temperature equivalent range is approximately 1050 - 1550F (560 to 850C).

NUMBER: 010 TO 3 - Made as a regular series (red, iron-containing cones) and as an Iron Free series for use in reducing atmospheres. These cones are used in the firing of craft and art bodies, for wall tile, glazes, and some structural clay products. The temperature equivalent range is approximately 1600-2150F (890 to 1170C).

NUMBER: 4 TO 12 - Used in firing porcelain, floor tile, china, stoneware, structural clay products and some refractory materials. The temperature equivalent range is approximately 2175-2345F (1180 to 1340C).

NUMBER: 13 TO 42 - Used for firing industrial products up to 3659F (2015C).

Here Is The Orton Cone Temperature Chart: (Download Complete Orton Cone Wall Chart Here.)

|

Cone Equivalent Temperatures (F)

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Self Supporting Cones 1 3/4" mounting height |

Large Cones |

Small 15/16" Height |

||||||||||

|

Regular |

Iron Free |

Regular |

Iron Free |

Regular |

PCE |

|||||||

|

Heating Rate (F/hour) |

Heating Rate (F/hour) |

|||||||||||

|

Cone |

27 |

108 |

270 |

27 |

108 |

270 |

108 |

270 |

108 |

270 |

540 |

270 |

|

022 |

1049 |

1087 |

1094 |

N/A |

N/A |

1166 |

||||||

|

021 |

1076 |

1112 |

1143 |

N/A |

N/A |

1189 |

||||||

|

020 |

1125 |

1159 |

1180 |

N/A |

N/A |

1231 |

||||||

|

019 |

1213 |

1252 |

1283 |

1249 |

1279 |

1333 |

||||||

|

018 |

1267 |

1319 |

1353 |

1314 |

1350 |

1386 |

||||||

|

017 |

1301 |

1360 |

1405 |

1357 |

1402 |

1443 |

||||||

|

016 |

1368 |

1422 |

1465 |

1416 |

1461 |

1517 |

||||||

|

015 |

1382 |

1456 |

1504 |

1450 |

1501 |

1549 |

||||||

|

014 |

1395 |

1485 |

1540 |

1485 |

1537 |

1598 |

||||||

|

013 |

1485 |

1539 |

1582 |

1539 |

1578 |

1616 |

||||||

|

012 |

1549 |

1582 |

1620 |

1576 |

1616 |

1652 |

||||||

|

011 |

1575 |

1607 |

1641 |

1603 |

1638 |

1679 |

||||||

|

010 |

1636 |

1657 |

1679 |

1600 |

1627 |

1639 |

1648 |

1675 |

1623 |

1636 |

1686 |

|

|

09 |

1665 |

1688 |

1706 |

1650 |

1686 |

1702 |

1683 |

1702 |

1683 |

1699 |

1751 |

|

|

08 |

1692 |

1728 |

1753 |

1695 |

1735 |

1755 |

1728 |

1749 |

1733 |

1751 |

1801 |

|

|

07 |

1764 |

1789 |

1809 |

1747 |

1780 |

1800 |

1783 |

1805 |

1778 |

1796 |

1846 |

|

|

06 |

1798 |

1828 |

1855 |

1776 |

1816 |

1828 |

1823 |

1852 |

1816 |

1825 |

1873 |

|

|

05½ |

1839 |

1859 |

1877 |

1814 |

1854 |

1870 |

1854 |

1873 |

1852 |

1868 |

1909 |

|

|

05 |

1870 |

1888 |

1911 |

1855 |

1899 |

1915 |

1886 |

1915 |

1890 |

1911 |

1944 |

|

|

04 |

1915 |

1945 |

1971 |

1909 |

1942 |

1956 |

1940 |

1958 |

1940 |

1953 |

2008 |

|

|

03 |

1960 |

1987 |

2019 |

1951 |

1990 |

1999 |

1987 |

2014 |

1989 |

1996 |

2068 |

|

|

02 |

1972 |

2016 |

2052 |

1983 |

2021 |

2039 |

2014 |

2048 |

2016 |

2035 |

2098 |

|

|

01 |

1999 |

2046 |

2080 |

2014 |

2053 |

2073 |

2043 |

2079 |

2052 |

2070 |

2152 |

|

|

1 |

2028 |

2079 |

2109 |

2046 |

2082 |

2098 |

2077 |

2109 |

2079 |

2095 |

2163 |

|

|

2 |

2034 |

2088 |

2127 |

2088 |

2124 |

2174 |

||||||

|

3 |

2039 |

2106 |

2138 |

2066 |

2109 |

2124 |

2106 |

2134 |

2104 |

2120 |

2185 |

|

|

4 |

2086 |

2124 |

2161 |

2120 |

2158 |

2208 |

||||||

|

5 |

2118 |

2167 |

2205 |

2163 |

2201 |

2230 |

||||||

|

5½ |

2133 |

2197 |

2237 |

N/A |

N/A |

N/A |

||||||

|

6 |

2165 |

2232 |

2269 |

2228 |

2266 |

2291 |

||||||

|

7 |

2194 |

2262 |

2295 |

2259 |

2291 |

2307 |

||||||

|

8 |

2212 |

2280 |

2320 |

2277 |

2316 |

2372 |

||||||

|

9 |

2235 |

2300 |

2336 |

2295 |

2332 |

2403 |

||||||

|

10 |

2284 |

2345 |

2381 |

2340 |

2377 |

2426 |

||||||

|

11 |

2322 |

2361 |

2399 |

2359 |

2394 |

2437 |

||||||

|

12 |

2345 |

2383 |

2419 |

2379 |

2419 |

2471 |

2439 |

|||||

|

13 |

2428 |

2458 |

2410 |

2455 |

2460 |

|||||||

|

13½ |

2466 |

2493 |

||||||||||

|

14 |

2489 |

2523 |

2530 |

2491 |

2548 |

|||||||

|

14½ |

2527 |

2568 |

||||||||||

|

15 |

2583 |

2602 |

2595 |

2608 |

2606 |

|||||||

|

15½ |

2617 |

2633 |

||||||||||

|

16 |

2655 |

2687 |

2651 |

2683 |

2716 |

|||||||

|

17 |

2694 |

2709 |

2691 |

2705 |

2754 |

|||||||

|

18 |

2736 |

2746 |

2732 |

2743 |

2772 |

|||||||

|

19 |

2772 |

2786 |

2768 |

2782 |

2806 |

|||||||

|

20 |

2811 |

2824 |

2808 |

2820 |

2847 |

|||||||

|

21 |

2851 |

2860 |

2847 |

2856 |

2883 |

|||||||

|

23 |

2890 |

2898 |

2887 |

2894 |

2921 |

|||||||

|

26 |

2892 |

2921 |

2950 |

|||||||||

|

27 |

2937 |

2961 |

2984 |

|||||||||

|

28 |

2946 |

2971 |

2995 |

|||||||||

|

29 |

2955 |

2993 |

3018 |

|||||||||

|

30 |

2977 |

3009 |

3029 |

|||||||||

|

31 |

3022 |

3054 |

3061 |

|||||||||

|

31½ |

3063 |

3088 |

3090 |

|||||||||

|

32 |

3103 |

3123 |

3123 |

|||||||||

|

32½ |

3124 |

3146 |

3135 |

|||||||||

|

33 |

3150 |

3166 |

3169 |

|||||||||

|

34 |

3195 |

3198 |

3205 |

|||||||||

|

35 |

3243 |

3243 |

3245 |

|||||||||

|

36 |

3268 |

3265 |

3279 |

|||||||||

|

37 |

3308 |

|||||||||||

|

38 |

3362 |

|||||||||||

|

39 |

3389 |

|||||||||||

|

40 |

3425 |

|||||||||||

|

41 |

3578 |

|||||||||||

|

42 |

3659 |

|||||||||||

You’re viewing 1-0 of 0 products

OUR PROCESS

Natural Sheffield Clay is mined on our property from as seen at one of the open clay pits. The Sheffield Clay deposit is located in Sheffield, Massachusetts, on U.S. Route 7 in the Southwest corner of Berkshire County.