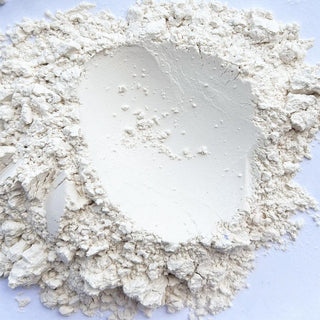

FLINT 325M / SIL-CO-SIL 52

Ground Silica

SIL-CO-SIL® Ground Silica products are produced from high purity silica, precision ground from 125 to 45 micron topsize. Our ground silicas are inherently inert, bright white, with low moisture and are at least 99.5% Si02.

FLINT - (SiO2) (m.p. 3119o F/1715o C) is the dark porous variety of chert that contains organic matter (chert is a hard, extremely dense, dull to semi-glossy sedimentary rock which is microcrystalline to cryptocrystalline quartz). True flint is very fine (cryptocrystalline) hydrated silica (1% molecular bound water) and is less dense than Quartz Sand due to a fine porous structure. The name flint is a carry over from England and France in which the true flints were prepared by calcination and grinding. Many geologists and archeologists suggest that the term flint be discarded or used only to identify artifacts of prehistoric humans (see also Silica).

SILICA - SiO2 (m.p. 3119oF/1715oC) is second only to clay in significance as a ceramic material, and it is the most abundant mineral in the earth’s crust. The principal siliceous materials are: Crystalline Quartz, Quartzite, Sandstone, Silica Sand, “Organic” and Amorphous Silica: including Flint and Diatomaceous Earth. Silica is frequently referred to as “Potter’s Flint” and is often just ground sandstone. It is used interchangeably with Quartz. Silica or Quartz is used in clay bodies to modify shrinkage, porosity, and strength (these modifications are affected by particle size and crystallinity). Quartz has a phase transition at 1063o F/573o C, i.e. the Quartz inversion. Upon firing, this inversion occurs rapidly and results in volume expansion, which can lead to firing cracks in clay bodies high in Free Quartz. In glazes, Silica is the most common glass former. It serves to control the fusibility and viscosity, which are dependent on the amount of Silica in the glaze. Typical mesh size of 200 (>74 microns), 325 (> 45 microns), and 400 (>30 microns) are offer varing applications in clay bodies and glazes. The coarser 200 mesh helps to control shrinkage while the finer 325 and 400 mesh are useful in glazes for their reactivity and ease of going into solution.

CUSTOMER REVIEWS - Q&A

Got a question about this product? Ask it here and get a response from our staff and also input from the Sheffield Pottery community!