North Star Clay Extruders

North Star Equipment Clay Extruders

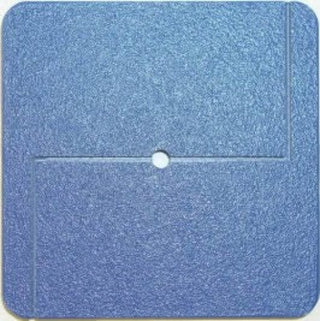

There are two North Star Equipment clay extruders offered here.

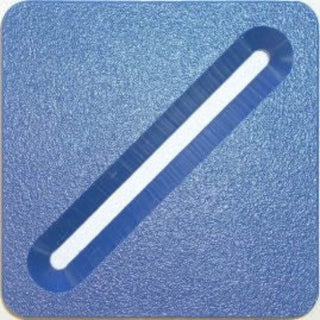

There is The Big Blue Extruder and the 4" stainless Extruders.

There are variations of the packages to accommodate your needs: one has more dies, one offers the 6" expander etc.

The Stainless and Standard models are identical in shape and capacity and any North Star standard die fits either one.

The Stainless Extruder and the Accessory Die Kit are packaged together at a money-saving price as the "Stainless Extruder Package." The Accessory Die Kit may also be purchased separately. (Jump to Dies and Die Sets Here)

"Why the stainless model ?"

The Stainless model offers the most versatility. This clay extruder can be used with just about any clay type as long as the clay is soft and easy to work with your hands. Because stainless steel won't rust, it is ideal for use with white stoneware clays and porcelain. If you're going to be using these clay types, then our Stainless extruder might be your best choice. The Stainless model is offer as a stand-alone unit, without dies, or in value-priced packages.

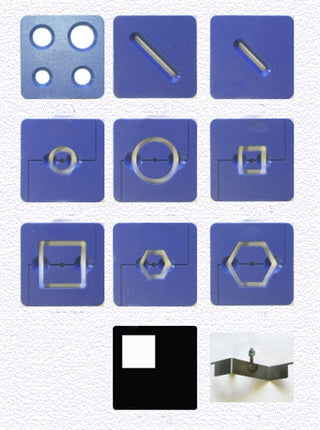

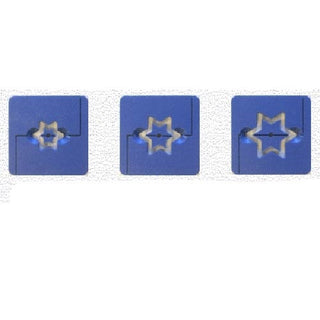

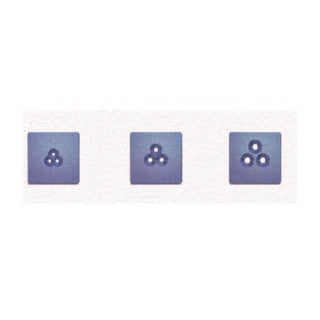

Every clay extruder comes with 8 coil dies, 2 handle dies, one square coil, one hex coil, a blank die and a die mask. Several of the coil dies contain 4 cavities of different sizes and the die mask is used to block off any three of them. The Accessory Die Kit, which may be purchased separately, contains a stainless steel Z-Bracket (die brace), 4 coil dies, 2 ribbon dies and 6 hollow dies. (Jump to Dies and Die Sets Here)

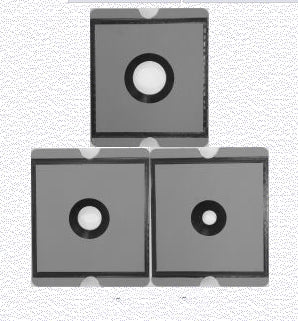

All dies are made of 1/2 inch thick polyethylene, which is extremely wear-resistant and completely non-contaminating. The top edge of the die cavity is beveled to compact the clay as it passes through, giving a crisp, more solid extrusion. In the hollow dies, there is a bevel on both the interior and exterior portions under each side of the bracket (which holds the center of the hollow dies) that helps the extrusion to "heal" after is has been cut apart by the bracket. This bracket fits into a Z-shaped slot machined into the top of the hollow die and is held in place by the barrel of the extruder. If a hollow die is mounted in place, the center part of the die is in exactly the right place and the wall thickness will automatically be even all the way around.

Note that in the stainless extruder, everything that comes in contact with the clay is either stainless steel or plastic and will not discolor the most delicate porcelain even if clay is left in the machine.

North Star Equipment 4" Stainless Extruder Package With Basic And Accessory Die Sets

$774.99

- Unit price

- /per

North Star Equipment Ultimate 4" Stainless Extruder Package With Many Dies And Z Brace!

$1,244.99

- Unit price

- /per

North Star Equipment Big Blue Medium Die Set Hollow Dies For Big Blue Extruder

$134.99

- Unit price

- /per

You’re viewing 1-40 of 40 products

North Star Equipment Clay Extruders

OUR PROCESS

Natural Sheffield Clay is mined on our property from as seen at one of the open clay pits. The Sheffield Clay deposit is located in Sheffield, Massachusetts, on U.S. Route 7 in the Southwest corner of Berkshire County.