Choose a sub category:

Olympic Raku and Torchbearer Gas Fired Kilns

See more about Raku Kilns and raku accessories in our Raku section: click here.Raku is an ancient Japanese technique that has been rediscovered by modern potters who appreciate its unique beauty and metallic luster and colors. The raku process involves reducing (starving the oxygen) the glazed raku pottery in combustible materials such as leaves, sawdust, newspaper, etc. When the pieces are ready to take out of the kiln, they are placed in galvanized trash containers with combustible materials and covered. Once the pieces are cooled down, they are removed from the containers, washed and reveal the rich warm effects of raku

Olympic Raku Kilns:

What every potter’s been waiting for ... a kiln that bisques, high fires (Cone 10), reduces, and best of all – is especially designed for raku work. It’s clean, easy, efficient and effortless.

The Olympic Raku kilns are constructed from durable firebrick and are available in three popular sizes. The firing chamber can be smoothly elevated by the turn of a hand winch, allowing easy access, while trapping the heat in the kiln and away from the operator. All Olympic Rakus are equipped with a venturi burner system to ensure even temperature firings.

The Olympic Raku kiln comes with a one-year warranty. Shelving, castors, and a pyrometer are available options.

Olympic Torchbearer Toploading Gas Kilns

Olympic Torchbearer Gas Kilns will fire to Cone 10/2350° Fusing natural gas or propane and are well suited for bisque, oxidation, and reduction firing.

The Olympic Torchbearer kilns are top loading, stackable gas kilns. These kilns are portable and rings can be added for additional depth without decreasing temperature range.

The Olympic Torchbearers use the same high-quality multiple venturi burner system configuration as the commercial Olympic DownDraft kilns. The multiple burner confi gurations provide even heating characteristics, fast controllable firing times, and economical operation. Olympic’s portable gas kilns offer many advantages such as low initial cost, convenient movement, simple maintenance, and use in situations where space does not permit installation of large permanent kilns

All Torchbearer Kilns are built in rings and may be easily enlarged with additional rings to conform exactly to your firing needs. (Adding kiln rings will not decrease firingtemperatures as in an electric kiln).

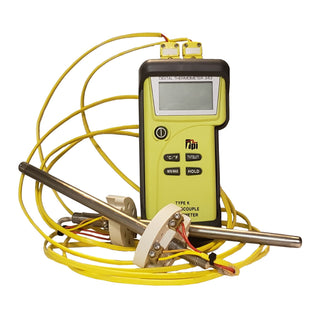

OPTIONS: Pyrometer, Kiln Sitter and Limit Timer.

Note: The prices shown for the Torchbearer and Raku kilns here include the Ignition Ring with Thermocouple Safety Shut-off

which adds a high degree of safety. We can supply these kilns without the Ignition ring but we feel that for safety's sake these should always be installed.

The ignition system is used to:

- Light the multiple burner system from one point

- Maintain the flame on each burner

- Re-ignite any burner that may extinguish

The thermocouple safety shut-off will stop the gas flow if the flame is lost entirely.

Burner Systems: The burners are included with these kilns: 23" or 28"

Kiln Sitter

can be added to these kilns

Kiln Sitter and Limit Timer

can be added to these kilns

| Inside Dimension | |||||||||||

| Model | Inches (Width) | Inches (Depth) | Cubic Feet | Maximum Temperature | BTU/BUR x1,000 | Max BTU/ Input | Gas Line Inlet | Orifice Size Natural Gas |

Orifice Size Propane | No. of Burners | Shipping Lbs. |

| 18 RAKU | 17 - 1/2 " | 22 - 1/2 " | 3.29 | 2350°F/Cone 10 | 60 | 120,000 | 3/4 " | 1/8 | 3/32 | 2 | 225 |

| 23 RAKU | 23 - 3/8 " | 27 " | 7 | 2350°F/Cone 10 | 80 | 240,000 | 3/4 " | 9/64 | #40 | 3 | 315 |

| 28 RAKU | 28 - 1/4 " | 27 " | 10 | 2350°F/Cone 10 | 70 | 280,000 | 3/4 " | 9/64 | #40 | 4 | 480 |

| 1827G | 17 - 1/2 " | 27 " | 3.95 | 2350°F/Cone 10 | 60 | 120,000 | 3/4 " | 1/8 | 3/32 | 2 | 205 |

| 18G BLANK RING | 17 - 1/2 " | 4 - 1/2 " | 0.66 | 30 | |||||||

| 2327G | 23 - 3/8 " | 27 " | 7 | 2350°F/Cone 10 | 80 | 240,000 | 3/4 " | 9/64 | #40 | 3 | 270 |

| 2331G | 23 - 3/8 " | 31 - 1/2 " | 8.15 | 2350°F/Cone 10 | 80 | 240,000 | 3/4 " | 9/64 | #40 | 3 | 318 |

| 23G BLANK RING | 23 - 3/8 " | 4 - 1/2 " | 1 | 40 | |||||||

| 2827G | 28 - 1/4 " | 27 " | 10 | 2350°F/Cone 10 | 70 | 280,000 | 3/4 " | Sep-64 | #40 | 4 | 396 |

| 2831G | 28 - 1/4 " | 31 - 1/2 " | 11.67 | 2350°F/Cone 10 | 70 | 280,000 | 3/4 " | Sep-64 | #40 | 4 | 420 |

| 28G BLANK RING | 28 - 1/4 " | 4 - 1/2 " | 1.67 | 86 |

OUR PROCESS

Natural Sheffield Clay is mined on our property from as seen at one of the open clay pits. The Sheffield Clay deposit is located in Sheffield, Massachusetts, on U.S. Route 7 in the Southwest corner of Berkshire County.